Industrial Metal Castings in Lancaster, PA

Industrial copper-based alloys are used widely in the metal casting industry because of their ability to economically deliver a wide range of properties. These advantages include:

- Strong electrical conductivity: Copper has the best electrical conductivity of any metal, except for silver. Copper alloys tend to provide superior conductivity, as well. High conductivity is desirable because it enables higher heat transfer and faster solidification.

- Pressure tightness: Copper-based alloys also provide superior pressure tightness. High-pressure tightness is desirable in casting because it allows the metal to hold a specified internal pressure and prevents leaking.

- Ductility: Copper alloys have an incredible ability to stretch under pressure without becoming damaged. This property makes them ideal for metal casting operations in which molten metal must flow without becoming brittle or porous.

- Ease of machinability: Copper-based alloys are easy to machine, using either traditional cutting tools or nontraditional techniques like electrical discharge machining (EDM). They allow for the crafting of parts that have various shapes and complexity.

- Corrosion resistance: Copper-based alloys are minimally susceptible to corrosion. They enable companies to create durable, corrosion-resistant parts that will not break down over time.

- Lead-free solutions: Many copper-based alloys are lead-free. They offer safe solutions for drinking water and food industry applications.

Using brass, which is an alloy of copper and zinc, or bronze, which is an alloy of copper, tin and often other metals, can help your company see these benefits in its equipment and products.

Importance of Quality in Industrial Metal Casting Processes

Metal casting such as copper, brass and bronze casting is key to creating machine parts for complex systems. Ninety percent of all manufactured goods contain some metal castings — the average person is rarely less than 10 feet from a cast metal part in daily life. So, ensuring the quality of industrial metal castings is essential, particularly for the following reasons:

- Safety in Industrial Applications: Systems like plumbing, electrical and fire protection systems can either become hazardous themselves or allow hazards to occur unchecked if they are not functioning correctly. Quality industrial metal castings help these systems continue operating effectively to keep people safe.

- Efficiency In Use: Machine parts that break down can cause equipment to lose efficiency. The machines may require more power to do less work or ultimately suffer failures. Quality metal castings help equipment continue functioning efficiently.

- Durability: Machine parts that often break down tend to require costly, time-consuming maintenance. But quality industrial metal casings have the durability needed to keep equipment running reliably over the long term with minimal maintenance requirements.

- Longevity of Material: Machine parts that break down can also ultimately cause total equipment failure and require even costlier replacements. Fortunately, quality industrial metal castings help extend equipment lifespans.

Industrial Foundry in Lancaster, PA

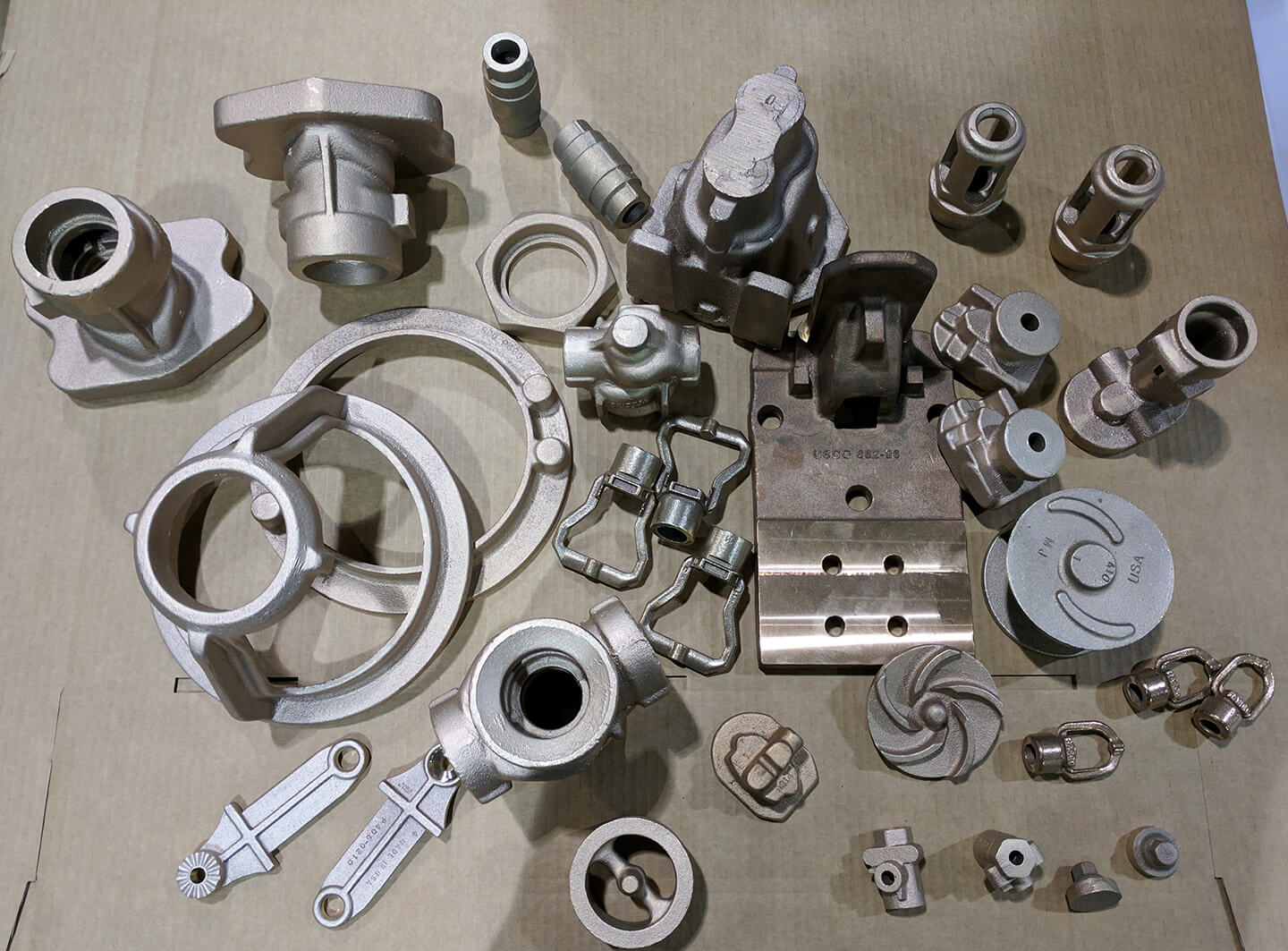

J. Walter Miller Company is a brass and bronze metal casting processing foundry that serves customers in the fire protection, plumbing, flow control and electrical industries. Some of the parts we provide include sprinkler heads, check valves, impellers, jet body castings, fittings, connectors and other engineered cast parts:

- Fire protection: We provide cast products like meal sprinkler heads for use in fire protection.

- Plumbing: We provide cast parts like metal fittings and metal pump parts to provide potable water.

- Flow control: We provide cast parts like metal check valves and impellers for use in flow control.

- Electrical industries: We provide cast parts like metal connectors and switch gears for use as electrical components.

Our industrial casting company has been in business for over 130 years, meaning we have tackled countless jobs in various industries.

Bronze, Copper and Brass Castings

To see the benefits of a bronze, brass and copper-casting foundry in Pennsylvania, partner with J. Walter Miller.

J. Walter Miller is a Lancaster, PA, industrial metal casting company that understands the unique needs of individual customers. Our metal foundry specializes in bronze, brass and copper castings — however, if you have a special request, we are happy to help!

Contact us today to get started on creating exactly what you need with our copper, brass and bronze-casting processes.

Reach Out To Our Team