About J. Walter Miller Company

19-year-old J.(Jacob) Walter Miller pioneers the metal electroplating and finishing business in Lancaster, PA. Born in Cumberland County, J. Walter moved back to his Father’s native Lancaster County, after his apprenticeship in Philadelphia with the J. Carrow Silver Company.

1887J. Walter Miller Company adds metal castings to the business and by 1897, the company opens a brass foundry. An advertisement from the period offered J. Walter Miller Company’s “Fine Bronze and Brass Castings of All Kinds.”

1888Charles R. Hitz, a molder at the foundry becomes a partner and briefly, the company is known as Miller and Hitz Brass Founders. The partnership dissolved by 1902.

1901Padlocks are starting to be produced and by 1907, we begin to see advertising for the J. Walter Miller Company line of high quality locks and hardware. A flier from that time period said, “Good Locks Are an Investment, Cheap Ones an Expense. Sell Quality and Satisfaction” Because the locks were of such high quality and produced for a relatively short period of time, they are highly treasured by collectors today

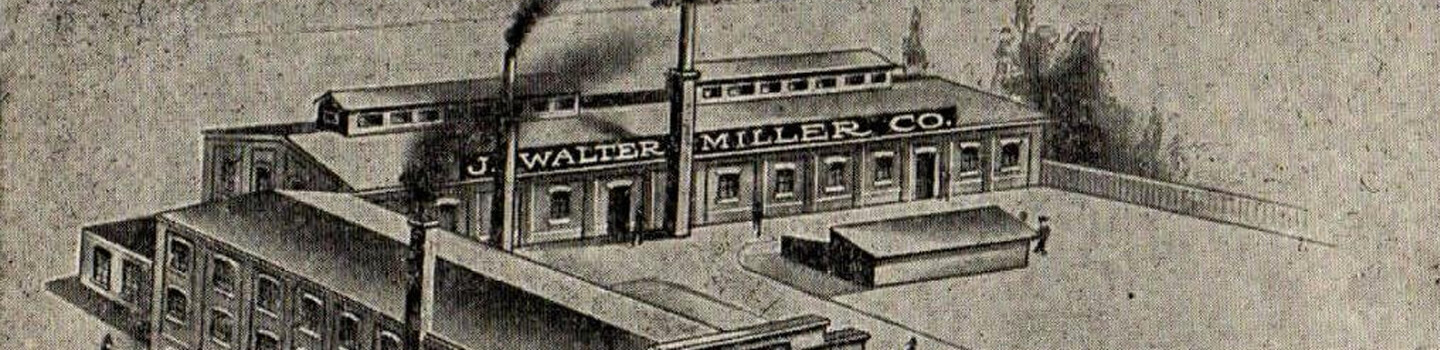

1904The company moved to its present location at 411 E. Chestnut Street, Lancaster, PA and became incorporated as the J. Walter Miller Company.

J. Walter was President and General Manager, Charles S. Bricker was Secretary/Treasurer and J. Walter’s wife Stella was on the Board of Directors.

As the United States entered the conflict, then called the Great War (and later World War I), J. Walter Miller joined the nationwide effort to support the troops. The Lancaster foundry made tent slips and machine gun parts as well as electro-galvanizing parts for airplanes, bombs, shells and other related needs

1906/1907J. Walter Miller’s only son Buster dies of Scarlett Fever at the age of 16 and the hope of the son taking over the business dies also. Daughter Elizabeth, who had a prominent music career (and a studio built by her Father right next to the business on Chestnut Street), became more active in the company’s management, working by her father’s side in the business.

1921The Magazine of Finance and Commerce produced a special addition in June of that year focusing on Lancaster and featuring J. Walter Miller as one of the leaders of the city’s industry. The magazine also had a somewhat optimistic outlook on the country’s financial state, although it alluded to “tension existing in the money markets…..” which possibly foretold the October stock market crash of that year that lead to the Great Depression.

1929Milton K. Morgan, Sr., a Franklin & Marshall graduate and husband of J. Walter Miller’s daughter Elizabeth, assumed the reins of the family business and began a succession of first-born Morgan sons into the family business.

1948Milton K. Morgan, Jr. joined the business after spending five years working for General Motors Central Foundry Division in Defiance, Ohio. A steady increase in orders for brass seat rings for malleable iron unions and sprinkler frames for the fire protection industry, satisfied Milt Jr’s quest for specialty items for the foundry. Aluminum, always a sideline, was phased out in the mid-1970’s.

1958Milton K Morgan III, who became the last decedent of J. Walter Miller to head the company, began to work with his father.

1980Milt III was named President of the Company with Milt Jr. still staying active in the business as CEO. The company began to look for ways to diversify.

1989Benchmark Construction built a new roof over the top of the entire existing foundry roof. This was done while carrying on business as usual, in order to meet customer needs. After completion of the new roof, the foundry shut down for two weeks, the old roof and walls were torn down from the inside and the foundry went back to running without a hitch.

1995The foundry industry held a trade show in Philadelphia. Loading any employee who wanted to go onto a bus, Milt III took his employees to Philadelphia so they could understand automatic molding. This was a move to move the foundry from all hand molding into a new era. A Sinto FBOII machine was purchased and installed at the foundry.

1996Another construction project connected the foundry to the office building and added additional square footage to the grinding area. One year later, the office was renovated and the “gas station” next door was connected to the office building to create an employee lunchroom. Also in 1998, the company tore down the Vondersmith building on its property to allow for more green space.

1998A 13,000-square-foot addition was built to provide a new finishing and shipping area.

1999A DISA Match 130 automatic molding machine, mold handling system, and pouring line replaced the remaining jolt squeeze stations.

2005Canerector, also a family owned business located in Toronto, Canada purchased the J. Walter Miller Company from Milton K. Morgan III, who retired.

2015The legacy of J. Walter Miller continues to thrive as a leader in casting in bronze and brass. The company continues to strive for excellence in quality, service and customer relations.

Future